The Fermentation Sciences pilot plant facility provides students with hands-on educational and research opportunities in recipe development and production. Fermentation Science courses at Appalachian State University provide rigorous coverage of the chemical and physical processes that go into production of beverages, from raw ingredients characterization to yeast and bacteria metabolism, and how these elements translate into a final product. These principles are a focal point of activities in the pilot plant where students are encouraged to think creatively and to consider how their knowledge can be applied to provide novel and innovative solutions to real-world challenges.

Recent awards from the US Department of Agriculture and North Carolina Biotechnology Center have allowed us to expand our pilot plant to handle volumes ranging from 1-gallon to 150-gallon processes as well as flow-through, immobilized bed reactors. The variable brewing and processing capacities provide students an opportunity to take bench trials up to a small, commercial-scale experience and the opportunity to run collaborative trials with commercial producers.

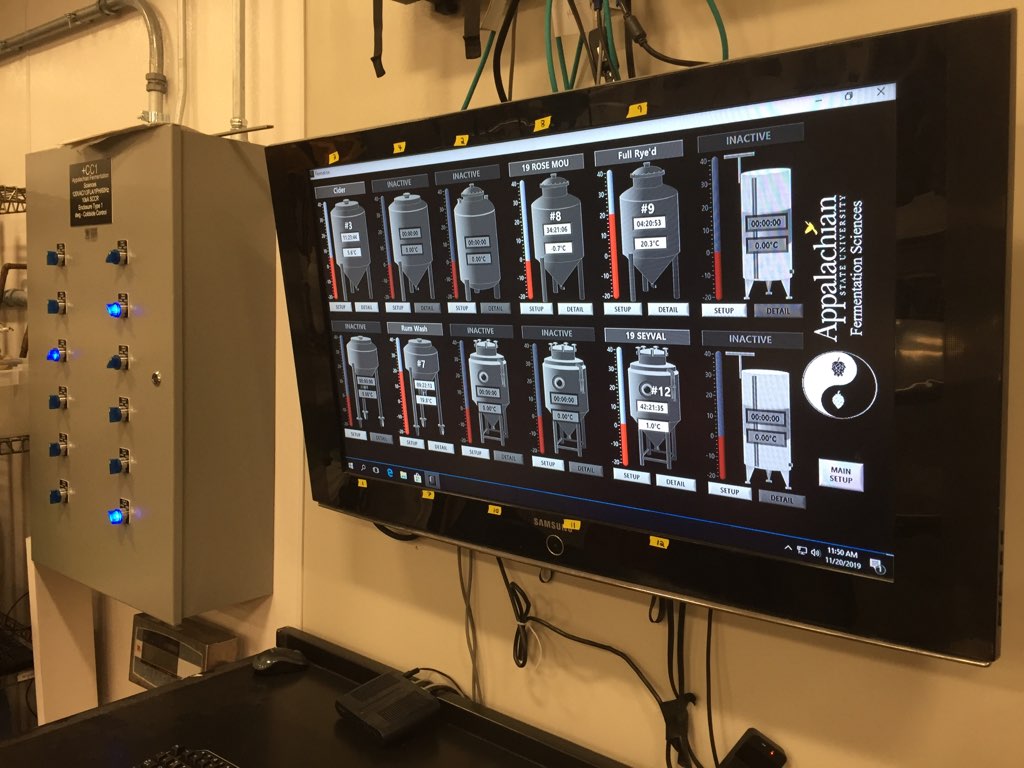

Students have worked to develop computer control and monitoring systems, cooling and heating solutions, options for process-water reclamation, increased energy efficiencies, uses for spent grains and solids, and efficient design and layout of the facility and laboratory.

Research Instrumentation & Equipment

Laboratories in the A.R. Smith Department of Chemistry and Fermentation Sciences are equipped with modern instrumentation which is used regularly by faculty and students:

Analytical Separations and Mass Spectrometry

- Gas Chromatography Mass Spectrometry (GC-MS)

- Agilent 7890B GC

- Agilent 5977B GC/MSD

- Gerstel Olfactory port

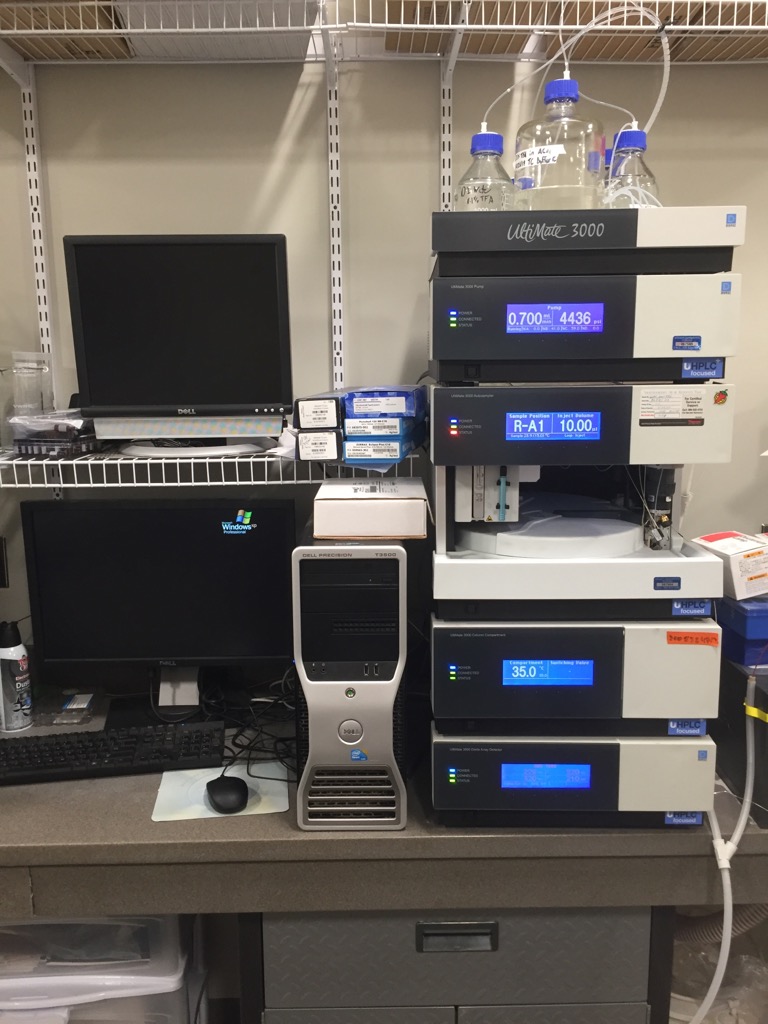

- High Performance Liquid Chromatography (HPLC) Coupled to LC/MS

- Dionex UltiMate 3000

- Dionex UltiMate 3000 120-vial autosampler

- Dionex UltiMate 3000 RS fluorescence detector

- Dionex UltiMate 3000 diode array detector

- Thermo Scientific Accela 200 vial autosampler

- Thermo Scientific LCQ Fleet

Molecular Spectroscopy

- Ultra-violet Visible (UV-Vis) Spectroscopy

- Spectramax M2e dual beam Microplate Reader with dual-mode cuvette ports

- Beckman Coulter DU 720 General purpose UV/Vis Spectrophotometer with 7 position carousel cuvette holder

Molecular Biology

- Safeaire Biosafety Cabinet with UV

- NAPCO 5410 water jacketed CO2 regulated incubator

- Tuttnauer 2540 Heidolph autoclave

- GelStudio Analytikjena

- Biometra TOne Cycler Analytikjena

- General Purpose Water Baths

- 4-Place Mini Bead Mill Homogenizer

- Midi 10 Electrophoresis System

- Eppendof centrifuge 5425

- Mini Horizontal Electrophoresis Systems

- SpectraMax QuickDrop Micro-Volume Spectrophotometer

- P-Series Portable Balances

- Mini Vortexer

- Power Supply

- MOTICAM X

- VWR MICROSCOPE PROF TRINCLR 3W LED 110V

- Power supply

- VWR FORCED AIR INCUBATOR 3.6CF 120V

- STERILIZER LARGE CAP LAB 115V W/DRYR 80L

- Two BIOCABINET

- Eppendorf centrifuge R 5430

Beverage Analysis

- Foss Winescan Flex

- Foss FiaStar Free and Total SO2 Analyzer with autosampler

- Anton-Paar 4500 DMA Densitometer

- Anton-Paar Alcolyzer with autosampler

Autotitrator

- Metler Toledo T50 autotitrator with 20 sample carousel autosampler

Brewing Equipment

- 3 barrel brewhouse with fully automatated control system

- 1/2 and 1 barrel brewhouse on propane burners

- Fully automated propylene glycol chiller system with Pro chiller MA series chiller.

- 3- Jacketed 1 barrel fermenters

- 2- Chiller wrapped ½ barrel fermenters

- 4- Jacketed 3 barrel fermenters

- 1- Jacketed 3 barrel brite tank

- 2- 600L variable top fermenters

- 4- 300L variable top fermenters

- Apple Shredder

- 1 ton Bladder filled press

- 1 ton Grape destemmer

- Criveller Company Wine filter

- Deutsche Beverage Distiller with steam generator